Why Are Cycling Product Prices Rising?

With the welcome increase in the popularity of cycling around the globe comes some unwelcome delivery delays - and now price increases. Here's a look at what's affecting the current situation for Ritchey.

Update - 04 Feb 2022 - Europe

Today we have increased Euro prices of components and frames by an average of 9%. This is specifically due to the loss of value that the EUR has suffered against the US dollar (around 6%) during last year and because of the continually increasing costs of shipping from Asia to Europe.

Begin original post

If there's one silver lining to be found around the very dark cloud that has been life during the pandemic, it's surely that more of our neighbors and people from every walk of life are discovering or re-discovering the joy of cycling – be it for pleasure, practicality, fitness, sanity, or a combination of all of it. Cycling is certainly enjoying its highest level of popularity in…well…forever, and that's awesome!

With this increased level of interest in cycling comes some business-side complications that have led to some frustrations for everyone from eager consumers to the people welding bikes in factories, to local shop owners, to bike company marketing hacks. Demand for any cycling product is at an all-time high but supply for those items is at historic lows. Supply will improve with time, but now we are facing another complication – the bike stuff you want is going to cost more.

Why are prices rising for bicycle-related goods?

After more than a decade of relatively modest price increases, "Fallout from the pandemic has thrown pricing stability and predictability out the window," says Riccardo Deliziosi, global director of sales and marketing for Ritchey.

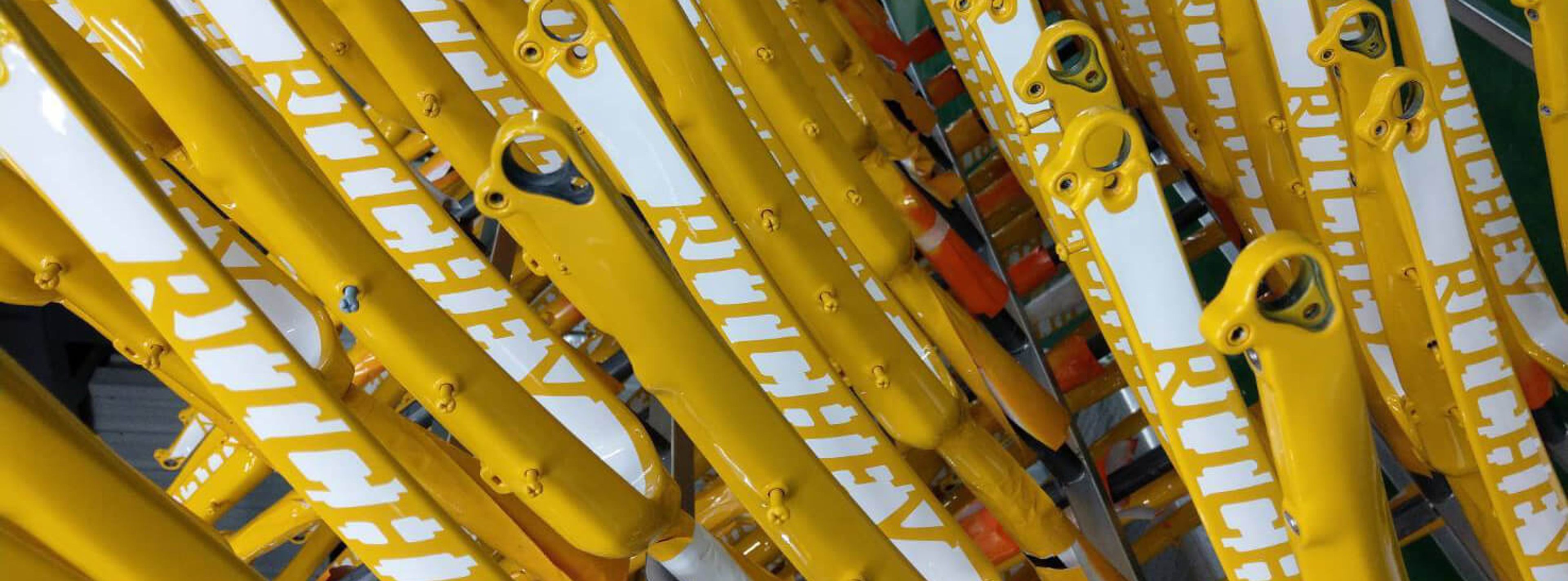

While we're unable to speak for other bike companies in the same situation, Deliziosi explains it like this: "Ritchey products are going to cost more because of higher prices for the raw materials needed to make the parts, labor shortages, energy problems, tightened shipping channels, and of course, Covid-19 restrictions and lockdowns."

Let's take a quick look at those points in a bit more detail.

Higher Raw Material Costs

Costs are rising for every material used to make a Ritchey product – steel, aluminum, and carbon fiber. Aluminum is particularly troublesome because it's the most expensive it's ever been - demand is at an all-time high, as many other industries have contributed to supply depletion. "Companies within and outside the bike industry are literally accepting whatever price they can get. There is no choice in the matter," explains Kevin Putzke, product development supervisor and general manager of Ritchey Asia.

Labor Shortage

Almost every Ritchey product is produced in Taiwan. When the pandemic first hit, factories across the country were shut and employees were sent home. But when the factories reopened, bringing back employees proved extremely difficult. One reason is because these factories employ many people from outside Taiwan. When borders closed, those workers were unable to return to the production lines. Additionally, Taiwan started another lockdown in early July of this year further tightening the already expensive labor pool within Taiwan.

Environmental and Energy Factors

Even before the pandemic, Taiwan was wrestling with a complicated mix of environmental and energy issues that directly impact all manufacturing in the country. "While the lack of typhoons hitting the country over the past few years is good for many reasons, it unfortunately means there have been less storms to leave behind acceptable levels of valuable water upon which the massive manufacturing sector of Taiwan relies," notes Putzke. Dealing with a drought, some factories are literally trucking in water for their production lines.

Additionally, over the past few years, many large companies have moved manufacturing out of mainland China into Taiwan. When these enormous new factories come online, not only do they squeeze out smaller companies (which includes most bike brands), it further stresses the already faltering energy resources needed for manufacturing.

Shipping Bottlenecks

By now you've surely seen news from around the world about the slow movement of products from factories to your front door - be it bicycles, automobiles, computers, shoes, phones, and just about anything else. The main reason for this shipping slowdown is that many crucial ports around the world have been suffering closures during the pandemic, causing a massive number of cargo ships to sit idle at times and then wait in long queues for loading or unloading. All of this has led to unprecedented scarcity of available shipping containers, the cost of which has multiplied fivefold in some cases.

What now?

While it's a complicated situation, the supply chain will slowly adapt to this new level of demand. Significant investments have been made to increase production capacity for many steps of bicycle and component production. Once these projects come online, prices may stop rallying and might even start to slowly decline.

We're all in this together and we're all going to need to ride this out a little bit. Ritchey has an unflinching commitment to produce the best quality bicycle products at the best possible prices. Every part of the Ritchey business is working extremely hard to reduce the waiting time for the bike stuff you want while also trying to soften and limit these higher costs. But rest assured that Ritchey will continue to use the highest quality materials and the most innovative production methods to produce the products you love without ever compromising just to save some money.

Join now for engaging stories, exclusive offers and product news delivered right to your inbox.